1995 – Where it all started.

On August 9th, 1995, with just £46 in the bank, we started out of 800sq ft of factory space making, in the first week, one window and door. At the time we had no lights, no racks, no kettle and not much chance. Our first advert in the local gazette felt a massive leap forward and laid the foundations for the start of our successful journey ahead.

2000s

2000 – Off into the deep end.

We signed for our first factory expansion, purchasing various new welding, cleaning and cutting tables. If you remember the petrol strike in 2000, at one point we were booking horse-drawn carts to transport our windows and doors.

2002 – The fire that should have broken us.

The factory fire of 2002 should also be mentioned after only two days of disruption we continued to manufacture windows in 4 inches of water with no lights and no roof.

2002 – Newbuild industry launch.

Our journey into newbuild market supplying all major house builders had begun. Over the years we have supplied, Barratts, Kensington’s, Persimmon, Taylor Wimpey, Avant, Lovells, Morris, Charles Church, Rowland homes to name a few.

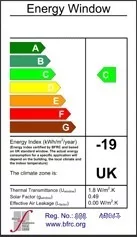

2004 – Launched first energy rated product (C rated).

We were one of the first companies in the UK to offer an energy rated product, launching the first BFRC certified window system. Energy ratings could now give customers an informed decision without the need for ‘sales jargon’. The certification made it easier to understand specifications. Even to this day, C-rated is being used by many window companies. If a manufacturer does not specify an energy rating, it is likely they offer C rated as standard.

2004 – Doubled the manufacturing facility.

We continued to grow and purchased multiple factories and depots.

2005 – Biggest investment moment.

2005 was both exciting and nerve wracking. We underwent a massive multi-million-pound expansion with the introduction of automated robotic machinery and an extra 16,000 sq. ft of new factory space to open a new manufacturing facility.

2006 – Opened Blackpool’s first window, door and conservatory showroom.

We decided it was time to change one of our factory units into the area’s first major showroom. A bold leap at the time, but a wise decision looking back. The showroom continues to grow in size and with a versatile product display. It continues to evolve today.

2008 – Showroom expansion.

Once we realised the showroom was crucial in showing customers our products. We decided the natural progression was to double the size. Even today the showroom continues to grow in product offering.

2007 – Launched upgraded specification (A rated).

We surpassed all companies and launched a window energy rating that was proven to lose zero heat. ‘A rated’ is still being used by 99% of window companies, a performance-based rating we achieved nearly two decades ago!

2010s

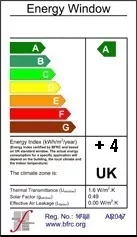

2010 – Launched upgraded spec (A+4 rated).

We surpassed all manufacturers introducing one of the first + category systems. We managed to accomplish this high standard with technologically advanced glazing and a new thermal insert. This energy rating meant customers could now go even further to reduce heating bills and save money.

2010 – Showroom refurbishment (Blackpool).

The showroom underwent an extensive refurbishment launching new conservatory and composite door designs.

2010 – First direct times paper sent to homes across the northwest.

We were advertising in every local newspaper across the Northwest. We came to conclusion that the natural progression was to print our own newspaper. Our demand to advertise in a tabloid that was exclusive to Direct Window Co created the format for today’s newspaper. After using various gazette newspapers to advertise, we decided to publish and deliver our very first Direct Times Newspaper in March 2010. We made every effort to protect the environment by printing on paper which is virtually 100% recycled. Over 1 million copies are delivered each month across the northwest of England.

2012 – Showroom refurbishment (Blackpool).

The showroom underwent an extensive refurbishment launching new windows and door displays.

2014 – Composite door manufacturing facility opened.

We modernised our range of composite door styles by investing in a new CNC cutting table. This versatile machine enabled us to provide some of the latest designs that are still being sold today.

2015 – Showroom refurbishment (Blackpool).

The showroom underwent an extensive refurbishment launching new style roofs and conservatory designs.

2016 – Launched bespoke colour range.

New colours were becoming more popular. Anthracite grey quickly became one of the ‘latest’ colour options. We decided to open a new spraying and drying unit to accommodate the new demand for bespoke colour window profile and composite doors.

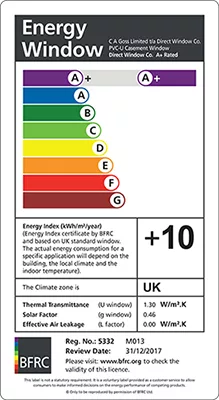

2017 – Launched upgrade spec (A+10 rated).

Always looking towards the future and finding innovative ways to stay ahead of the game. It meant taking our performance rating to the next level. We hit double digits with our new exclusive window system. completely surpassing all other companies

2019 – Opened Preston Showroom.

Covering Lancashire meant many customers wanted a showroom that was within easy reach.

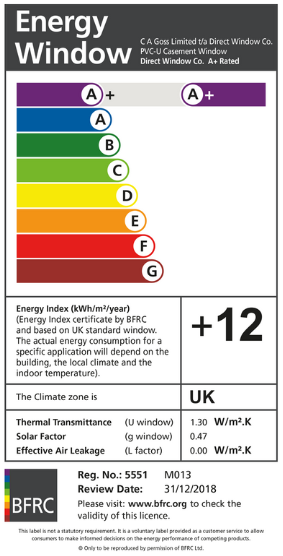

2019 – Launched upgrade spec (A+12 rated).

We decided to introduce one of the best energy ratings in the UK to-date and making it affordable too. We understood not many people buy windows twice in their lifetime so it was crucial to make sure they get the best specification they could for their money.

2020s

2021 – Launched sustainable insulating roof systems.

Eco insulating systems were born and quickly became one of greatest products for insulating an old or new conservatory.

2022 – Launched integral blinds.

One of favourite product launches, we introduced integral window and door blinds across our showrooms.

2023 – Massive refurbishment across both showrooms.

We introduced 6 new garden rooms across all showrooms. New sustainable conservatory designs and the stunning orangery 2.0.

2023 – Launched sustainable garden rooms

The Eco Garden Room was launched, built to last by using sustainable materials which are maintenance free, waterproof and planet friendly. A cost-effective way of providing more space without the need of a costly extension. The thermally efficient garden room offers stunning design and high insulation. The internal eco frame has inbuilt insulated panels with waterproof cladding (available in multiple colour upgrades).

2023 – Launched new orangery design (Ultimate Orangery)

Check out the interior design on the new orangery in our Blackpool Showroom. The grand roof façade is a high-line fascia system with an inbuilt hidden gutter. This epic roof style is complemented by flush sash windows with quadrilateral white bars. The visual presence of this new orangery screams sophistication.

2023 – Launched new sustainable conservatory design.

The new Eco Annex Launch. If you’ve had the 20-year-old conservatory, too hot in summer too cold in winter, you might want to consider the next generation of insulated hybrids. Opulent vertical styled pillars, elegant roof design, a huge amount of insulation and an increase in internal usable space.